Water Jet Cutting: How We Got Here

Water jet cutting is the preferred method of fabrication when working with materials sensitive to temperatures. API/AMS employs top quality in-water jet technology for our metal fabrication process: the Flow-Allen/Bradley water jet. But do you know how water jets came to be such a pillar of metal fabrication?

Water jet cutting is the preferred method of fabrication when working with materials sensitive to temperatures. API/AMS employs top quality in-water jet technology for our metal fabrication process: the Flow-Allen/Bradley water jet. But do you know how water jets came to be such a pillar of metal fabrication?

From a humble beginning

High-pressure water as a tool has been in use for centuries, notably in hydraulic mining back in the 1800s. But water wasn’t seen as an industrial cutting tool until the 1930s, when a water jet was used to cut paper. Compared with our high-pressure water systems now, the water jet used at that time was fairly low pressure and could only cut soft materials.

Later, in the 1950s, researchers were able to construct water jet systems using a pressure pump, creating jets that could part high strength alloys, and a pulsing water jet able to cut stone as well as metals. The method of cutting soft materials was also improved by the use of long chain polymers that were dissolved in the water to solidify the jet stream.

Jet improvements

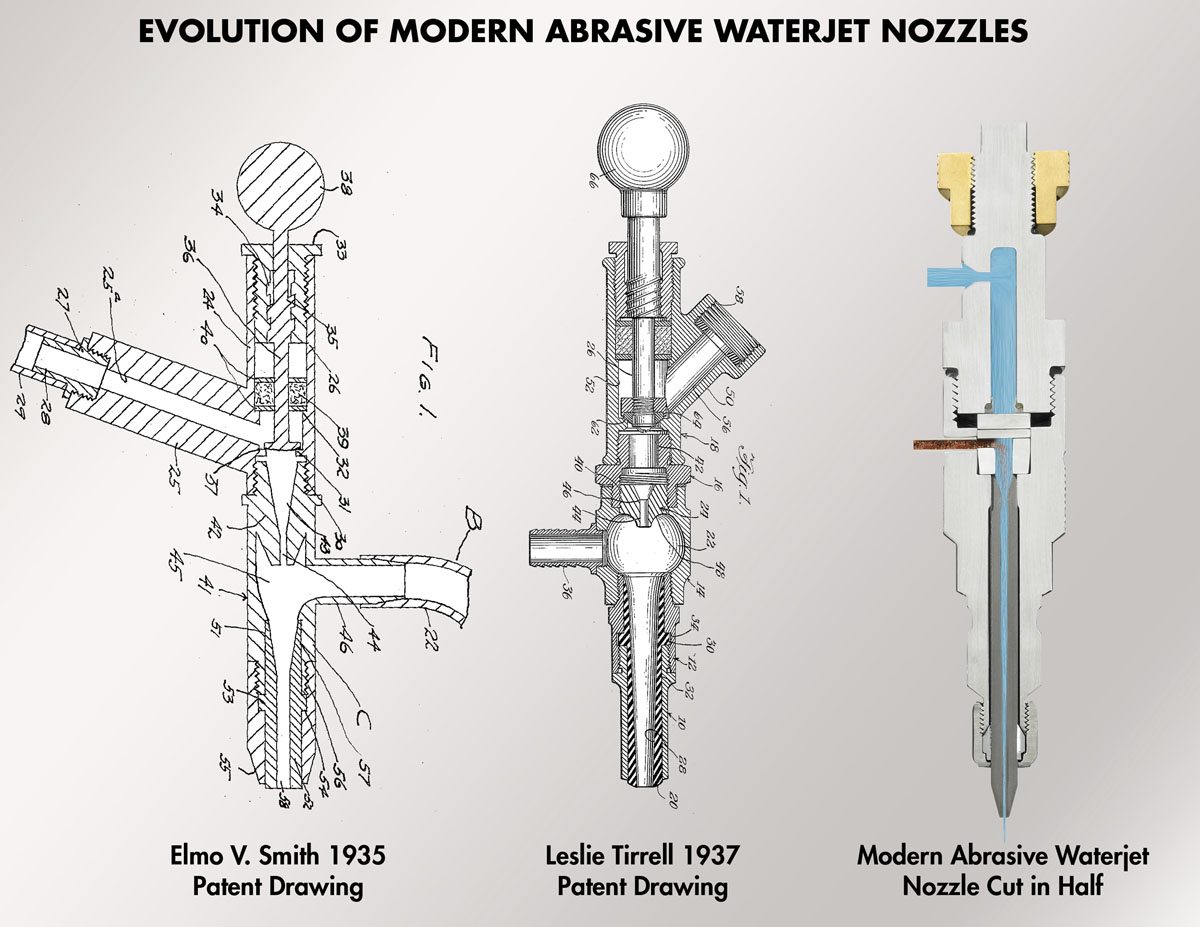

Improvements were made to the water jet nozzle as well. In the 1970s, the innovation of using a corundum crystal for the water jet orifice upped the pressure even higher. Scientists also learned that treating water prior to using it in the water jet increased the longevity of the nozzle’s life.

Finally, the inclusion of an abrasive medium really brought water jet cutting to the forefront of metal fabrication. Water jets now use micro-abrasive products that allow the jet nozzle to remain small, thus keeping the pressure up as high as possible while the abrasive mixture aids in a smooth, clean cut.

At API/AMS, count on quality

The use of water in industry has been around since the steam engine, but API/AMS’s use of water looks like the Starship Enterprise compared to the Union Pacific’s famed steam locomotives. Our use of precision water jet cutting is at the top of its technological field, and climbing every day.

At API/AMS, we don’t just build on history, we make history.

Call us today to learn more about our precision machining and metal fabrication.