Identifying the Most Important CAD Trends of 2020

CAD technology and trends have evolved significantly over the last year, not to mention the last decade. Commonly, manufacturers will hear terms like machine learning, virtual reality, and artificial intelligence thrown around when it comes to CAD trends, but how much do these types of advancements really apply to how you run your business and attempt to meet your 2020 revenue goals?

For some, hearing the word “trend” immediately causes eyes to roll. After all, how often does the latest this or the most advanced that really revolutionize business? Sure, for every new virtual reality toy or machine learning gizmo that comes out on the market, very few actually make a perceptible dent in how manufacturers do business. However, just because few trends actually catch on for the long-term doesn’t mean there’s no value in understanding what direction future technologies may take the industry in.

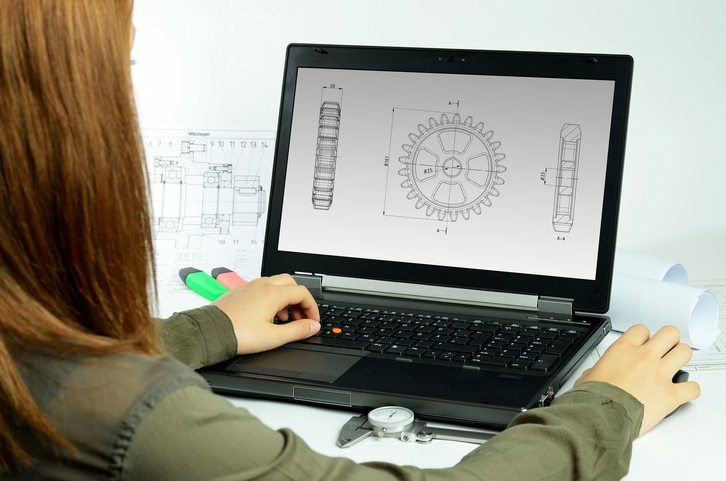

With that in mind, let’s take a look at a few important trends surrounding 3D CAD models that could end up impacting your daily business and bottom line.

The Top Ranked CAD Trend is 3D Modeling

In 2019, Business Advantage published its latest CAD trends report, which detailed all of the current and upcoming trends that those in the CAD business need to know. The report surveyed over 600 CAD users and industrial decision makers to identify and rank 16 topics related to CAD by their perceived level of importance and ability to impact the industry over the next five years.

Again, 3D modeling was at the top of the list for current usage, importance and awareness among those surveyed. Roughly 81 percent of participants were aware of the growing role 3D modeling in manufacturing, and 69 percent stated they were already using the technology as part of their careers.

While trends like machine learning and virtual reality tend to grab headlines as the most exciting advances in CAD technology, the results of the survey found that the market still remains largely focused on 3D modeling and 2D drafting.

Moving forward, Business Advantage predicted that 3D modeling will remain the top trend in manufacturing over the next five years.

Native CAD Downloads and Instant Configuration

From the beginning, the overarching theory when it came to 3D CAD downloads was to make it as easy as possible for designers, architects, and engineers to complete their work.

A need for manufacturers to represent themselves digitally to their customers requires they do more than make STEP files available.

Engineers expect to access high-quality product data files that incorporate digital designs and 3D imagining when accessing a manufacturer’s website. A STEP file offers only the minimum an engineer can use when developing product models in their CAD systems. This requires engineers to make some serious concessions: STEP files don’t allow engineers to change set parameters or design intent – two key features that most businesses now expect when downloading product information.

Moving into 2020, manufactures will need to provide native CAD model downloads to their customers in whatever CAD format they’d prefer. This will enable customers to receive the product data in ways that are useable to them, while also maintaining a manufacturer’s ability to track downloads as future sales leads.

3D Product Cataloging

As manufacturers continue to grow their understanding of customer need and expectation, they often look toward 3D product catalogs as the preferred CAD delivery mechanism.

These type of product catalogs offer digital customer experience that engineers need while still delivering the digital CAD models they require. 3D catalogs enable manufacturers to provide instantaneous CAD downloads in native formats quickly and with technical product datasheets.

Manufacturers who don’t offer 3D cataloging or an equivalent solution run the risk of being considered behind the times, and may see their sales migrate towards more digitally-savvy businesses.

BIM Files Offer New Opportunities to Connect

Building Information Materials, or Building Information Modeling, (BIM) has become an emerging trend with solid growth potential, according to the survey conducted by Business Advantage. Almost 50 percent of participants reported currently using or planing to use BIM within the next three to five years.

What could this mean for manufacturing? For industries that build products for both architectural and engineering customers, providing BIM files as native downloads offers a huge competitive edge.

BIM is the preferred file type used by architects, and architectural firms have chosen BIM as the standard for product information. Not surprisingly, the most effective way manufacturers can connect with architects is through their website. According to a study from the American Institute of Architects, 85 percent of architects visit manufacturer websites to find product information and keep up on product trends.

Since architects state that manufacturer websites help to influence what products they buy, and that manufacturer websites are the top spot architects go to find new building materials, it only makes since that manufacturers provide their audience with the most useful information in the file format they prefer – BIM.

More 3D Models Are Being Downloaded Than Ever Before

In recent years, manufacturers have seen a significant increase in the number of users regularly downloading 3D models.

Nearly 25 percent of participants in the Business Advantage survey reported they download models 10 or more times a month. Roughly 57 percent said they download parts at least once a month.

Business Advantage indicates this increase is simply part of the growing frequency and regularity of CAD files being downloaded by businesses in the U.S. industrial sector. As a greater number of manufacturers embrace technologies that support 3D Cam and BIM delivery, the number of downloads will only continue to increase.